Textile muscles is a young research field that originated in Sweden at Linköping University and the University of Borås. In the long run, the technology can be built into clothes that can give an extra boost during heavy lifting, give hugs at a distance and help the visually impaired navigate the urban environment.

“When we say exoskeleton, we see in front of us an almost robotic figure with clumsy mechanical parts. But with textile muscles, long underwear woven from our yarn might be enough to provide extra strength when, for example, heavy lifting,” says Edwin Jager, professor at Linköping University.

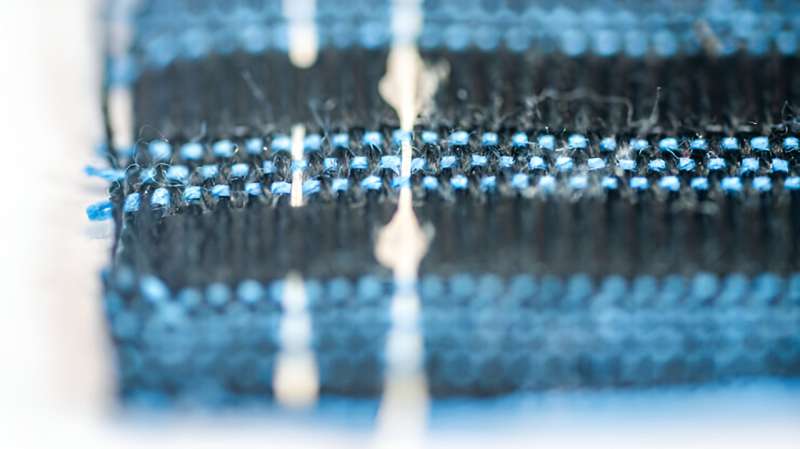

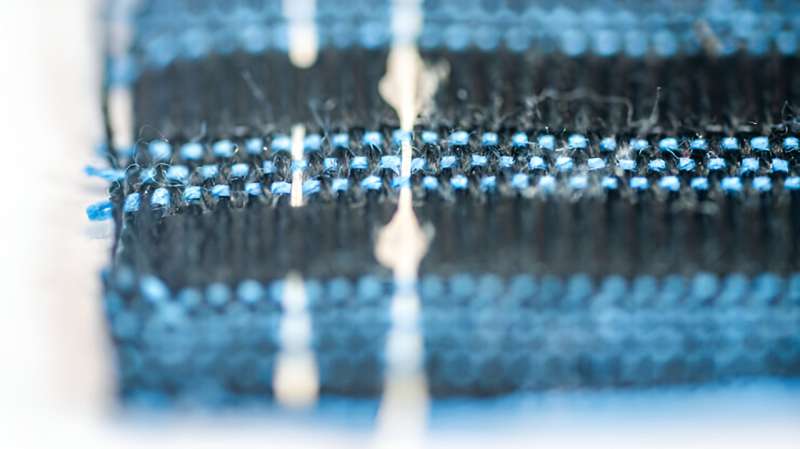

In 2017, his research team, together with researchers at the University of Borås, showed how an ordinary thread with a coating of conductive plastics (PEDOT and polypyrrole) can be stretched and shrunk when subjected to an electrical current. This news received considerable attention.

But a single thread does not have high tenacity. Therefore, the researchers parallel connect several threads and weave them together into one fabric. The tenacity is then much higher. However, the dynamics of a moving fabric are far more complex than you might first think.

At the University of Borås, there are a number of researchers studying fabric and textiles.

“We are in contact with textiles 99 percent of our lives—the clothes you wear, the sheets you sleep in and the car you drive. There’s also a huge potential to weave smart textiles that can be helpful in everyday life for many people,” says Carin Backe, Ph.D. student at the Department of Textile Technology at the University of Borås.

Her research area is textile material technology with a focus on textile structures for mechanical actuation and touch communication (haptics). And haptic communication is the area where research in textile muscles has come closest to practical application.

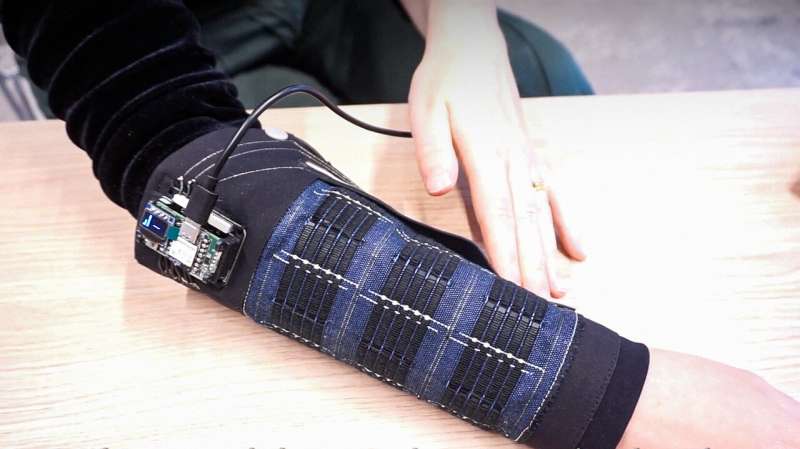

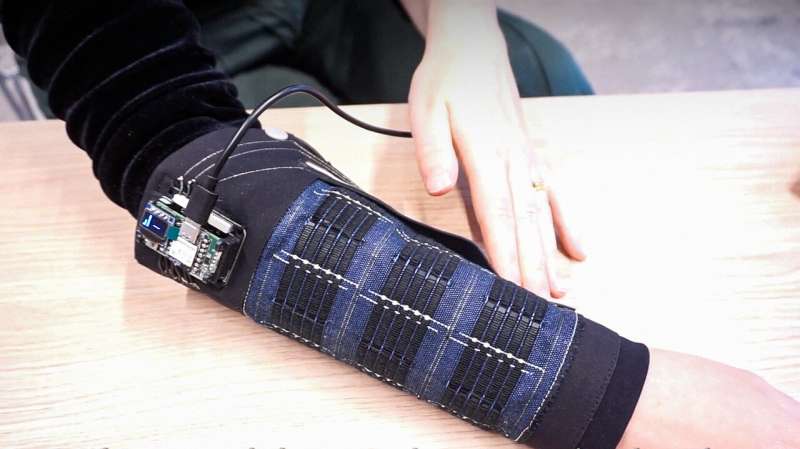

In a recently completed Horizon 2020 project, the research groups at LiU and the University of Borås, together with the University of Twente in the Netherlands, CY Cergy Paris University in France, and the companies Elitac Wearables and Wearable Technologies, have developed a sleeve with woven textile muscles that can provide haptic feedback.

“We focused on haptics in the project because the textile muscles are currently a bit too weak and slow to function like actual muscles,” says Backe.

The researchers were able to show how the sleeve can be used for social touching at a distance. The users each wear a sleeve that is connected to its own computer. When one person stroked their own sleeve, the other felt the stroke through their sleeve.

What happens is that integrated sensors feel the pressure of the person doing the stroking. These signals are passed on to the receiver’s sleeve, where the textile contracts due to the textile muscles. This creates pressure on the skin that is perceived as a touch. But the technology is not only useful for couples longing for proximity in a distant relationship.

“For the visually impaired, it could be an option to get information about surroundings through their clothes to facilitate navigation in, for example, urban environments,” says Jager.

He thinks that it could also be used in the gaming industry as a complement to VR that enhances the experience of a game. For example, you could feel pressure on your body when you get shot in a game.

“That’s where the big money is right now. This is perhaps the direction you must go to commercialize the product initially. After that, you can invest in other more interesting applications that benefit society,” says Jager.

The next step for the research is to increase the weight that each textile muscle can lift. In the long term, the vision is to make entire items of clothing where textile muscles are integrated. These would provide a soft exoskeleton that is not visible on the outside.

“In the care of older persons, it would be an excellent option both for the staff, who could then avoid repetitive strain injuries from heavy lifting, and for the older persons who can get a boost when they get up. But it could also be relevant for construction workers and others who have a lot of heavy lifting in their jobs,” says Jager.

The Horizon 2020 project, called Weafing, has now been completed, but research and collaboration between LiU and the University of Borås continues thanks to a grant of SEK 6 million from the Erling Persson Foundation, which has supported the research since 2017. Nils-Krister Persson, senior lecturer at the University of Borås, thinks that they have only scratched the surface of the technology’s potential:

“The fact is that we have muscle fibers in our body, and who are experts on fibers if not the textile world? There is much we can be inspired by from nature and realize in textile. After the scientific successes, we look forward to developing an innovation that can benefit people,” he says.

According to Jager, development is progressing rapidly, and we may see the first functioning soft exoskeleton in the not-too-distant future, and says, “I’m very pleased because in 2017 we had a small yarn thread that moved and only worked in liquid, and now we have a fully functional prototype sleeve. I think it’s fantastic that we’ve managed to come all this way in only seven years.”

Linköping University

Fabric coated in conductive plastics will soon give your clothes extra muscles (2024, August 7)

retrieved 7 August 2024

from https://techxplore.com/news/2024-08-fabric-coated-plastics-extra-muscles.html

part may be reproduced without the written permission. The content is provided for information purposes only.

Textile muscles is a young research field that originated in Sweden at Linköping University and the University of Borås. In the long run, the technology can be built into clothes that can give an extra boost during heavy lifting, give hugs at a distance and help the visually impaired navigate the urban environment.

“When we say exoskeleton, we see in front of us an almost robotic figure with clumsy mechanical parts. But with textile muscles, long underwear woven from our yarn might be enough to provide extra strength when, for example, heavy lifting,” says Edwin Jager, professor at Linköping University.

In 2017, his research team, together with researchers at the University of Borås, showed how an ordinary thread with a coating of conductive plastics (PEDOT and polypyrrole) can be stretched and shrunk when subjected to an electrical current. This news received considerable attention.

But a single thread does not have high tenacity. Therefore, the researchers parallel connect several threads and weave them together into one fabric. The tenacity is then much higher. However, the dynamics of a moving fabric are far more complex than you might first think.

At the University of Borås, there are a number of researchers studying fabric and textiles.

“We are in contact with textiles 99 percent of our lives—the clothes you wear, the sheets you sleep in and the car you drive. There’s also a huge potential to weave smart textiles that can be helpful in everyday life for many people,” says Carin Backe, Ph.D. student at the Department of Textile Technology at the University of Borås.

Her research area is textile material technology with a focus on textile structures for mechanical actuation and touch communication (haptics). And haptic communication is the area where research in textile muscles has come closest to practical application.

In a recently completed Horizon 2020 project, the research groups at LiU and the University of Borås, together with the University of Twente in the Netherlands, CY Cergy Paris University in France, and the companies Elitac Wearables and Wearable Technologies, have developed a sleeve with woven textile muscles that can provide haptic feedback.

“We focused on haptics in the project because the textile muscles are currently a bit too weak and slow to function like actual muscles,” says Backe.

The researchers were able to show how the sleeve can be used for social touching at a distance. The users each wear a sleeve that is connected to its own computer. When one person stroked their own sleeve, the other felt the stroke through their sleeve.

What happens is that integrated sensors feel the pressure of the person doing the stroking. These signals are passed on to the receiver’s sleeve, where the textile contracts due to the textile muscles. This creates pressure on the skin that is perceived as a touch. But the technology is not only useful for couples longing for proximity in a distant relationship.

“For the visually impaired, it could be an option to get information about surroundings through their clothes to facilitate navigation in, for example, urban environments,” says Jager.

He thinks that it could also be used in the gaming industry as a complement to VR that enhances the experience of a game. For example, you could feel pressure on your body when you get shot in a game.

“That’s where the big money is right now. This is perhaps the direction you must go to commercialize the product initially. After that, you can invest in other more interesting applications that benefit society,” says Jager.

The next step for the research is to increase the weight that each textile muscle can lift. In the long term, the vision is to make entire items of clothing where textile muscles are integrated. These would provide a soft exoskeleton that is not visible on the outside.

“In the care of older persons, it would be an excellent option both for the staff, who could then avoid repetitive strain injuries from heavy lifting, and for the older persons who can get a boost when they get up. But it could also be relevant for construction workers and others who have a lot of heavy lifting in their jobs,” says Jager.

The Horizon 2020 project, called Weafing, has now been completed, but research and collaboration between LiU and the University of Borås continues thanks to a grant of SEK 6 million from the Erling Persson Foundation, which has supported the research since 2017. Nils-Krister Persson, senior lecturer at the University of Borås, thinks that they have only scratched the surface of the technology’s potential:

“The fact is that we have muscle fibers in our body, and who are experts on fibers if not the textile world? There is much we can be inspired by from nature and realize in textile. After the scientific successes, we look forward to developing an innovation that can benefit people,” he says.

According to Jager, development is progressing rapidly, and we may see the first functioning soft exoskeleton in the not-too-distant future, and says, “I’m very pleased because in 2017 we had a small yarn thread that moved and only worked in liquid, and now we have a fully functional prototype sleeve. I think it’s fantastic that we’ve managed to come all this way in only seven years.”

Linköping University

Fabric coated in conductive plastics will soon give your clothes extra muscles (2024, August 7)

retrieved 7 August 2024

from https://techxplore.com/news/2024-08-fabric-coated-plastics-extra-muscles.html

part may be reproduced without the written permission. The content is provided for information purposes only.