The safety and efficiency of a large, complex nuclear reactor can be enhanced by hardware as simple as a tiny sensor that monitors a cooling system. That’s why researchers at the Department of Energy’s Oak Ridge National Laboratory are working to make those basic sensors more accurate by pairing them with electronics that can withstand the intense radiation inside a reactor.

The ORNL research team recently met with unexpectedly high success using a gallium nitride semiconductor for sensor electronics. A transistor made with the material maintained operations near the core of a nuclear reactor operated by research partner The Ohio State University.

Gallium nitride, a wide-bandgap semiconductor, had previously been tested against the ionizing radiation encountered when rockets hurtle through space. Devices with wide-bandgap semiconductors can operate at much higher frequencies, temperatures and irradiation rates. But gallium nitride had not faced the even more intense radiation of neutron bombardment.

“We are showing it is great for this neutron environment,” said lead researcher Kyle Reed, a member of the Sensors and Electronics group at ORNL.

That could offer a big boost for equipment monitoring in nuclear facilities. The information gathered by sensors provides early warnings about wear and tear on equipment, allowing timely maintenance to avoid broader equipment failures that cause reactor downtime. Currently, this sensing data is processed from a distance, through yards of cable connected to electronics with silicon-based transistors.

“Our work makes measuring the conditions inside an operating nuclear reactor more robust and accurate,” Reed said. “When you have lengthy cables, you end up with a lot of noise, which can interfere with the accuracy of the sensor information. By placing electronics closer to a sensor, you increase its accuracy and precision.” To meet that goal, scientists need to develop electronics that can better tolerate radiation.

Researchers irradiated gallium nitride transistors for three days at temperatures up to 125 degrees Celsius close to the core of The Ohio State University Research Reactor.

“We fully expected to kill the transistors on the third day, and they survived,” Reed said. The team pushed the transistors all the way to the reactor’s safety threshold: seven hours at 90% power.

The gallium nitride transistors were able to handle at least 100 times higher accumulated dose of radiation than a standard silicon device, said researcher Dianne Ezell, leader of ORNL’s Nuclear and Extreme Environment Measurements group and a member of the transistor research team.

She said the transistor material must be capable of surviving at least five years, the normal maintenance window, in the pool of a nuclear reactor. After the research team exposed the gallium nitride device to days of much higher radiation levels within the core itself, they concluded that the transistors would exceed that requirement.

This is an important technical advance as attention turns from the large-scale existing fleet of nuclear energy plants to microreactors that could generate from tens to hundreds of megawatts of power. Although these novel reactor designs are still in the development and licensing stage, their potential portability could allow them to be deployed on the back of a truck to a military or disaster zone.

Advanced reactors are being designed to operate at higher temperatures using different forms of fuel. Because microreactors will be so compact, all the operating components, including the sensors, will have to be able to function in the radiation field, Ezell said. Gallium nitride transistors could be the key.

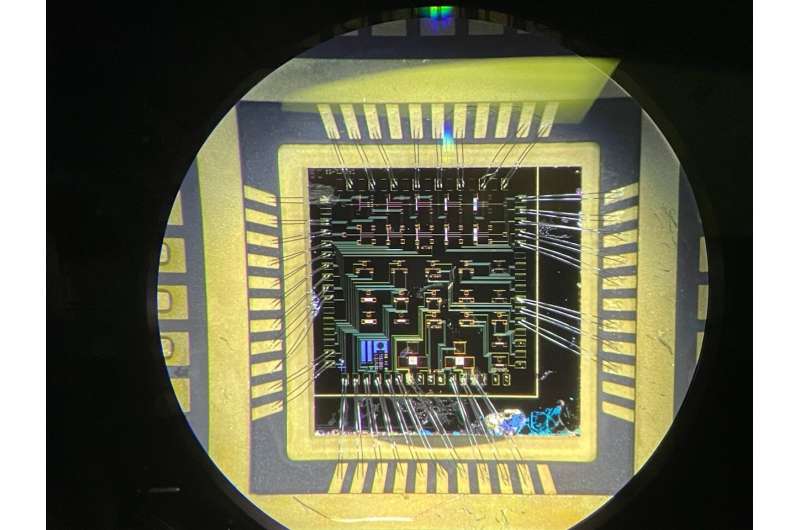

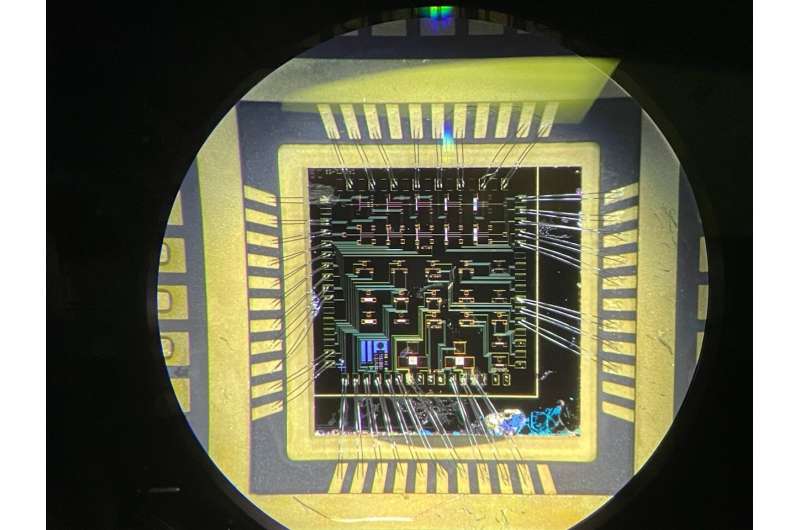

Ohio State researchers built devices of different designs and sizes to meet specifications set by ORNL, and then the team compared their responses to radiation, finding that larger devices seemed less susceptible to radiation damage. Ohio State is now developing computer models to project how various circuit designs will perform under different temperatures and radiation levels.

Reed said the radiation testing at Ohio State showed that heat seemed to be more harmful to the gallium nitride than radiation, so the research team wants to measure how gallium nitride reacts to heat alone.

“Since the ultimate goal is to design circuits with these materials, once we understand the temperature and radiation effects, we can compensate for them in the circuit design,” Reed said.

Better nuclear monitoring means increased safety and reduced operating costs, Ezell noted. “Hundreds of thousands of dollars are lost every day a reactor is shut down,” she said. “If we’re going to make nuclear economically competitive with other energy industries, we’ve got to keep our costs low.” Plus, reducing the frequency of maintenance reduces human safety risks. “You’re able to avoid putting people in harsh radiation environments or handling radioactive material as often,” Ezell added.

Although gallium nitride has been commercially available for around a decade, it’s not widely used, Reed said.

“We’re opening up different side avenues for using gallium nitride, so we can start to create a more reasonable market demand for investment, research and workforce development for subclasses of electronics beyond consumer-grade,” Reed said.

In the long run, researchers would like to demonstrate that gallium nitride circuits could be used to transmit data from sensors wirelessly. The material is already used for devices that support radio frequency applications, like cell phones, and for power electronics.

ORNL researchers, staff and interns including Nance Ericson, Brett Witherspoon, Craig Gray, Emma Brown, Adam Buchalter, Caleb Damron and former intern Kevin Deng also contributed to the project.

Oak Ridge National Laboratory

Hardy transistor material could be game-changer for nuclear reactor safety monitoring (2024, June 24)

retrieved 24 June 2024

from https://techxplore.com/news/2024-06-hardy-transistor-material-game-changer.html

part may be reproduced without the written permission. The content is provided for information purposes only.

The safety and efficiency of a large, complex nuclear reactor can be enhanced by hardware as simple as a tiny sensor that monitors a cooling system. That’s why researchers at the Department of Energy’s Oak Ridge National Laboratory are working to make those basic sensors more accurate by pairing them with electronics that can withstand the intense radiation inside a reactor.

The ORNL research team recently met with unexpectedly high success using a gallium nitride semiconductor for sensor electronics. A transistor made with the material maintained operations near the core of a nuclear reactor operated by research partner The Ohio State University.

Gallium nitride, a wide-bandgap semiconductor, had previously been tested against the ionizing radiation encountered when rockets hurtle through space. Devices with wide-bandgap semiconductors can operate at much higher frequencies, temperatures and irradiation rates. But gallium nitride had not faced the even more intense radiation of neutron bombardment.

“We are showing it is great for this neutron environment,” said lead researcher Kyle Reed, a member of the Sensors and Electronics group at ORNL.

That could offer a big boost for equipment monitoring in nuclear facilities. The information gathered by sensors provides early warnings about wear and tear on equipment, allowing timely maintenance to avoid broader equipment failures that cause reactor downtime. Currently, this sensing data is processed from a distance, through yards of cable connected to electronics with silicon-based transistors.

“Our work makes measuring the conditions inside an operating nuclear reactor more robust and accurate,” Reed said. “When you have lengthy cables, you end up with a lot of noise, which can interfere with the accuracy of the sensor information. By placing electronics closer to a sensor, you increase its accuracy and precision.” To meet that goal, scientists need to develop electronics that can better tolerate radiation.

Researchers irradiated gallium nitride transistors for three days at temperatures up to 125 degrees Celsius close to the core of The Ohio State University Research Reactor.

“We fully expected to kill the transistors on the third day, and they survived,” Reed said. The team pushed the transistors all the way to the reactor’s safety threshold: seven hours at 90% power.

The gallium nitride transistors were able to handle at least 100 times higher accumulated dose of radiation than a standard silicon device, said researcher Dianne Ezell, leader of ORNL’s Nuclear and Extreme Environment Measurements group and a member of the transistor research team.

She said the transistor material must be capable of surviving at least five years, the normal maintenance window, in the pool of a nuclear reactor. After the research team exposed the gallium nitride device to days of much higher radiation levels within the core itself, they concluded that the transistors would exceed that requirement.

This is an important technical advance as attention turns from the large-scale existing fleet of nuclear energy plants to microreactors that could generate from tens to hundreds of megawatts of power. Although these novel reactor designs are still in the development and licensing stage, their potential portability could allow them to be deployed on the back of a truck to a military or disaster zone.

Advanced reactors are being designed to operate at higher temperatures using different forms of fuel. Because microreactors will be so compact, all the operating components, including the sensors, will have to be able to function in the radiation field, Ezell said. Gallium nitride transistors could be the key.

Ohio State researchers built devices of different designs and sizes to meet specifications set by ORNL, and then the team compared their responses to radiation, finding that larger devices seemed less susceptible to radiation damage. Ohio State is now developing computer models to project how various circuit designs will perform under different temperatures and radiation levels.

Reed said the radiation testing at Ohio State showed that heat seemed to be more harmful to the gallium nitride than radiation, so the research team wants to measure how gallium nitride reacts to heat alone.

“Since the ultimate goal is to design circuits with these materials, once we understand the temperature and radiation effects, we can compensate for them in the circuit design,” Reed said.

Better nuclear monitoring means increased safety and reduced operating costs, Ezell noted. “Hundreds of thousands of dollars are lost every day a reactor is shut down,” she said. “If we’re going to make nuclear economically competitive with other energy industries, we’ve got to keep our costs low.” Plus, reducing the frequency of maintenance reduces human safety risks. “You’re able to avoid putting people in harsh radiation environments or handling radioactive material as often,” Ezell added.

Although gallium nitride has been commercially available for around a decade, it’s not widely used, Reed said.

“We’re opening up different side avenues for using gallium nitride, so we can start to create a more reasonable market demand for investment, research and workforce development for subclasses of electronics beyond consumer-grade,” Reed said.

In the long run, researchers would like to demonstrate that gallium nitride circuits could be used to transmit data from sensors wirelessly. The material is already used for devices that support radio frequency applications, like cell phones, and for power electronics.

ORNL researchers, staff and interns including Nance Ericson, Brett Witherspoon, Craig Gray, Emma Brown, Adam Buchalter, Caleb Damron and former intern Kevin Deng also contributed to the project.

Oak Ridge National Laboratory

Hardy transistor material could be game-changer for nuclear reactor safety monitoring (2024, June 24)

retrieved 24 June 2024

from https://techxplore.com/news/2024-06-hardy-transistor-material-game-changer.html

part may be reproduced without the written permission. The content is provided for information purposes only.